Every year we make investments in new technologies that allow us not only to increase quality and production performance, but also to continuously improve factors such as safety, energy consumption and environmental impact.

Springfix has since the very beginning organised its production to include the manufacturing of parts through metal forming, plastic injection molding and various assembly processes. With an unwavering commitment to innovation and the highest quality standards, we keep abreast of industry trends and new technologies, offering our customers in the automotive industry high-performance and precise solutions.

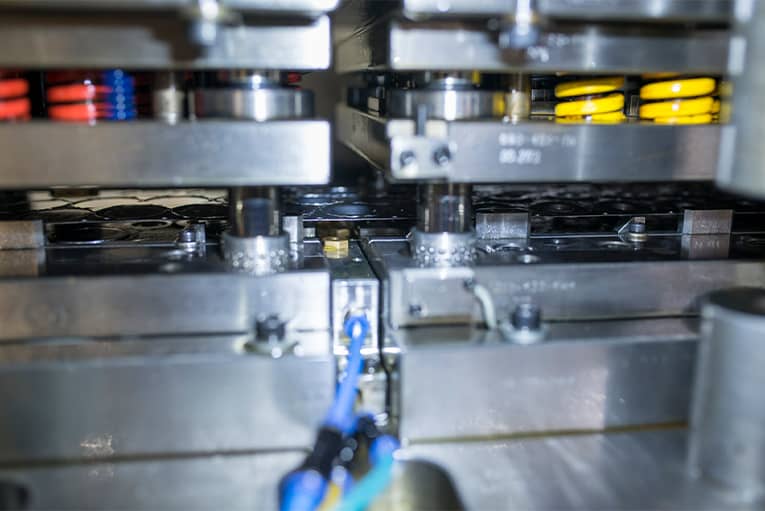

Bihler machines are sophisticated manufacturing machines designed for the high-precision production of intricate metal components. The machining centers utilize a multi-slide technology, which allows them to efficiently and precisely shape, bend, cut, and assemble metal materials. They are particularly useful for tasks that demand tight tolerances and complex geometries.

These presses, which range from 40 to 160 tons, are robust machines used in the metal forming processes at Springfix.

The wire technologies encompass a range of manufacturing processes and machinery used in working with wire-based materials. At Springfix, these processes include wire forming, welding, cutting, and other techniques that transform wire into various shapes.

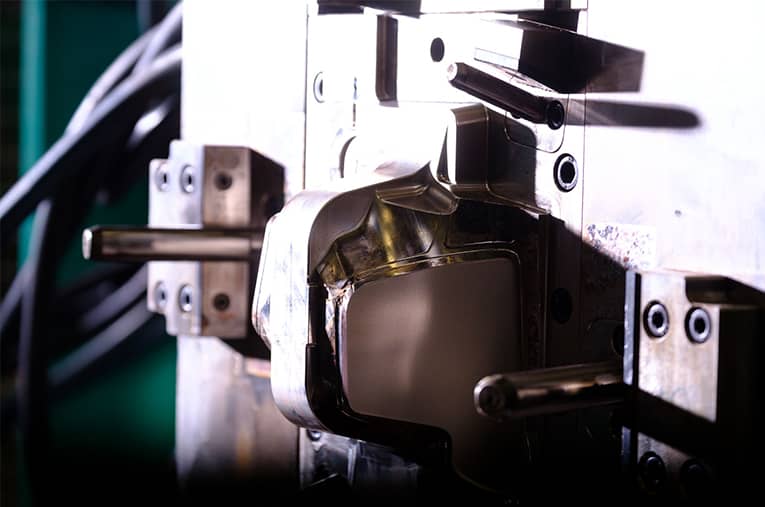

At Springfix, injection molding presses with capacities of up to 500 tons are used in the plastic manufacturing process. These presses are designed to precisely and efficiently produce our plastic parts and components. These machines work by injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired part. The choice of press capacity depends on the specific requirements of the molding project, including the size, complexity, and quantity of parts to be produced. One example is the 2K Machinery, a two-component injection molding system that enables the production of components using two different materials or colors in a single molding cycle. At Springfix they are widely employed to create complex and multi-functional parts. This technology enhances design flexibility and reduces the need for additional assembly steps.

Assembly is a fundamental manufacturing process where individual parts or components are joined together to create a finished product. At Springfix, this process may involve automated machinery, or robotics, depending on the complexity and scale of production. Assembly is a critical stage in manufacturing diverse of the parts Springfix offers.